Dustproof Belt Alignment System

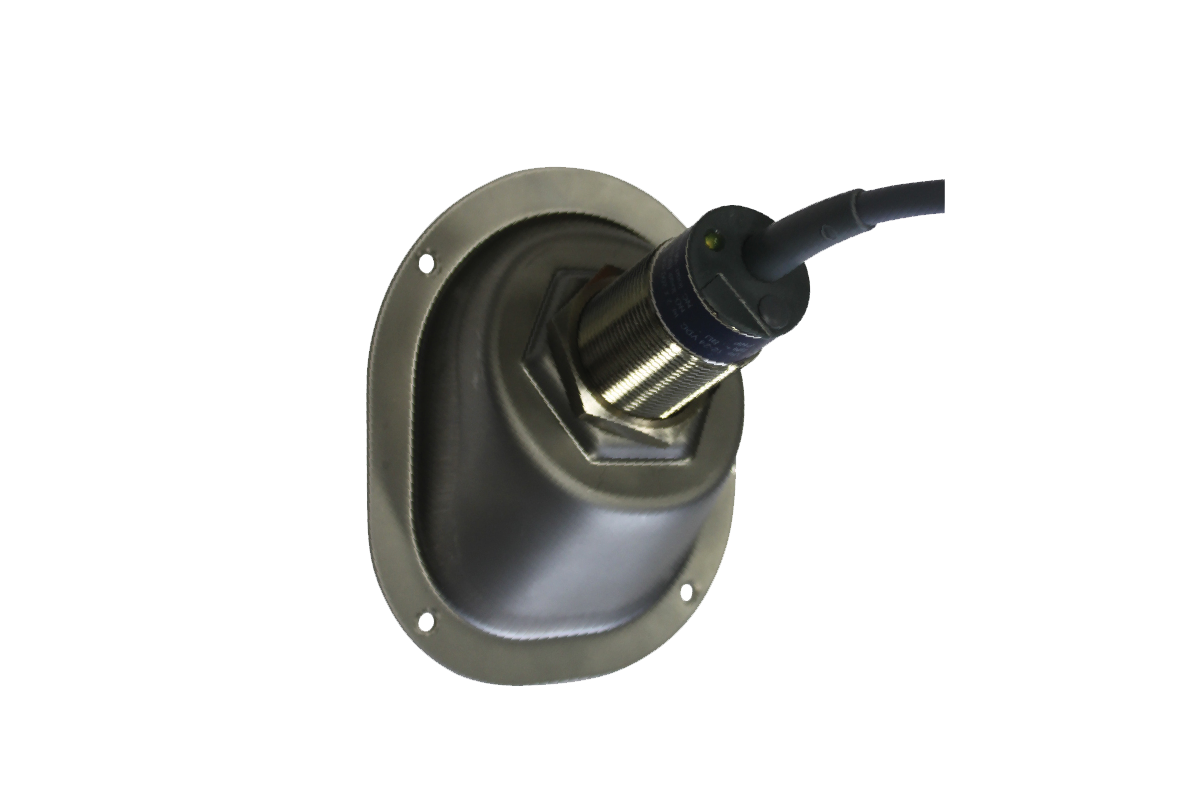

Product code: VigiBelt Touch, Vigibelt CDM80C

Applications

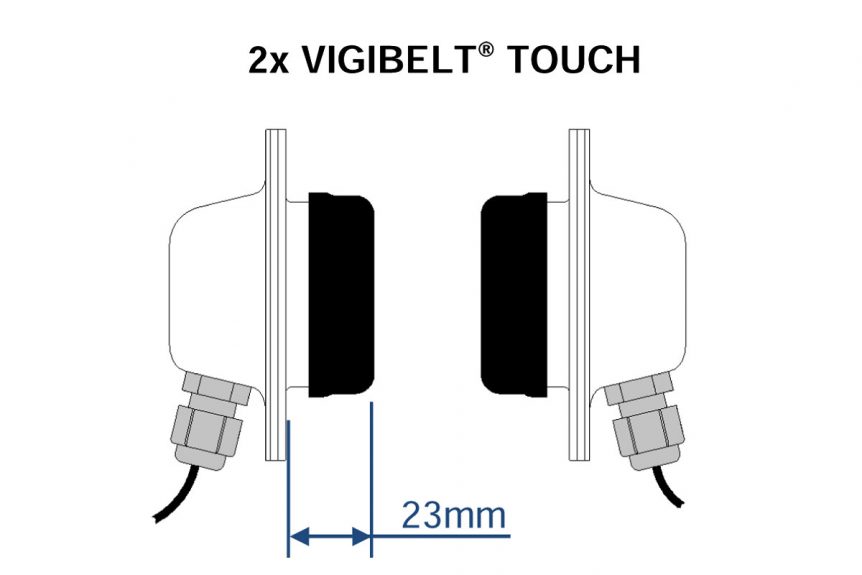

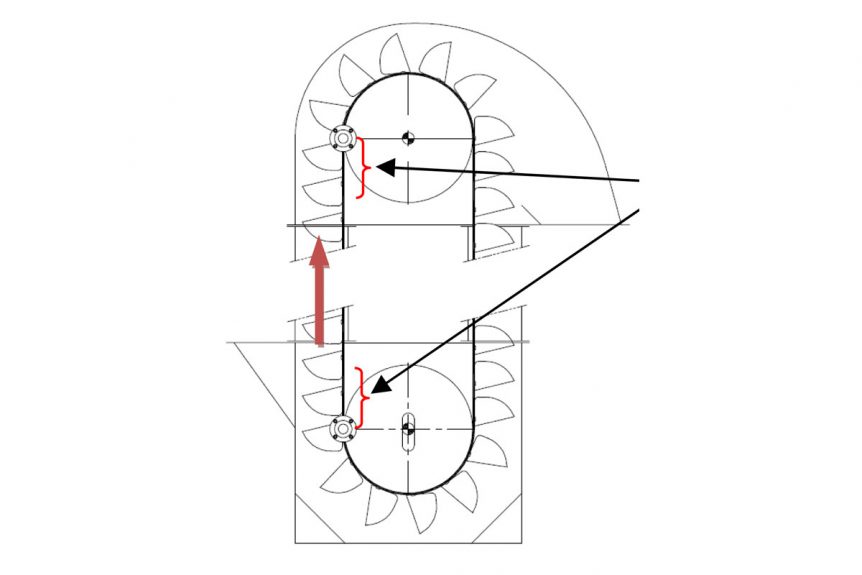

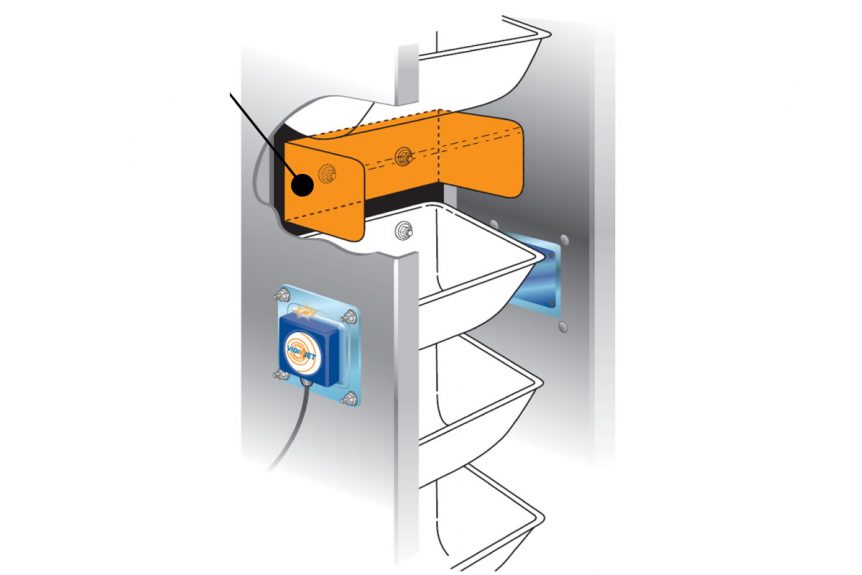

The VIGIBELT® TOUCH is a lateral movement sensor that detects run-out of elevator belts or conveyor belts, and at the same time the run-out of the lift pulley. It reacts to the pressure of the belt coming into contact with the front face of the sensor. Baffle plates are usually fitted opposite each other, preferably on the upward leg close to the pulleys for elevators, and on the load bearing side close to the drums for conveyors. The sensors, which trigger when the belt applies a force of approximately 5 daN, can be connected directly to a PLC, or for absolutely safety, to an independent "monitoring M-JET” central unit. The electrical circuit can control an alarm or a machine shut down. For elevators more than 20 meters long, we recommend fitting the head with a second VIGIBELT® TOUCH kit, still on the upward leg.

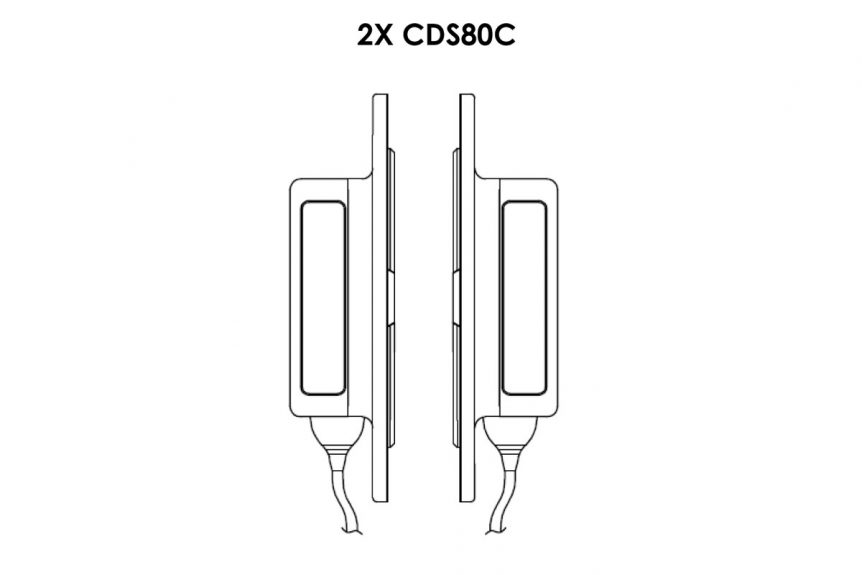

The VIGIBELT CDM80C® is an elevator belt alignment system which has to be placed on an elevator in order to avoid any friction between the belt and the inner sides of the elevator’s leg. The CDS80C VIGIBELT® has to be installed by pair on the going-up leg, above the elevator’s foot. As far as elevators higher than 20 meters are concerned, the head also has to be equipped on the up-going leg. One or several targets also have to be installed on the elevator’s belt (at about every 30 meters) to enable an even more accurate control.

Get More Information on This Product

"*" indicates required fields