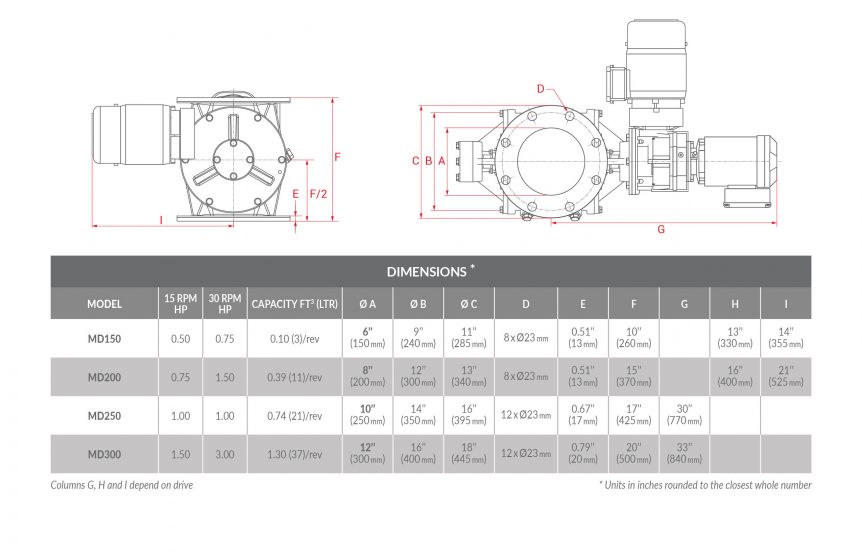

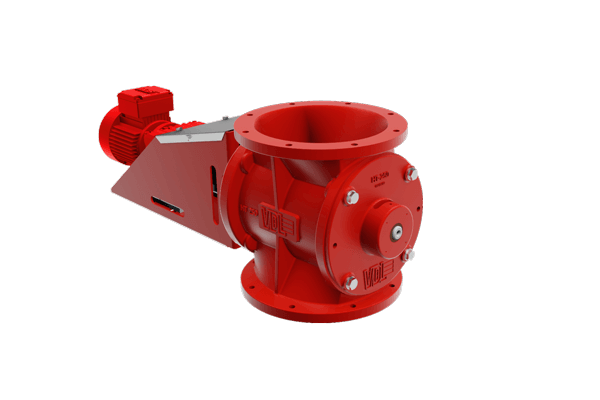

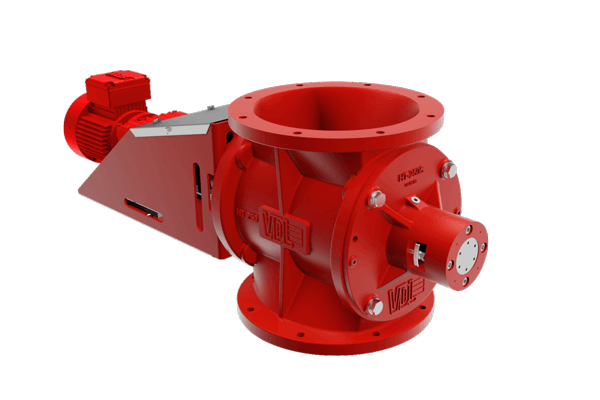

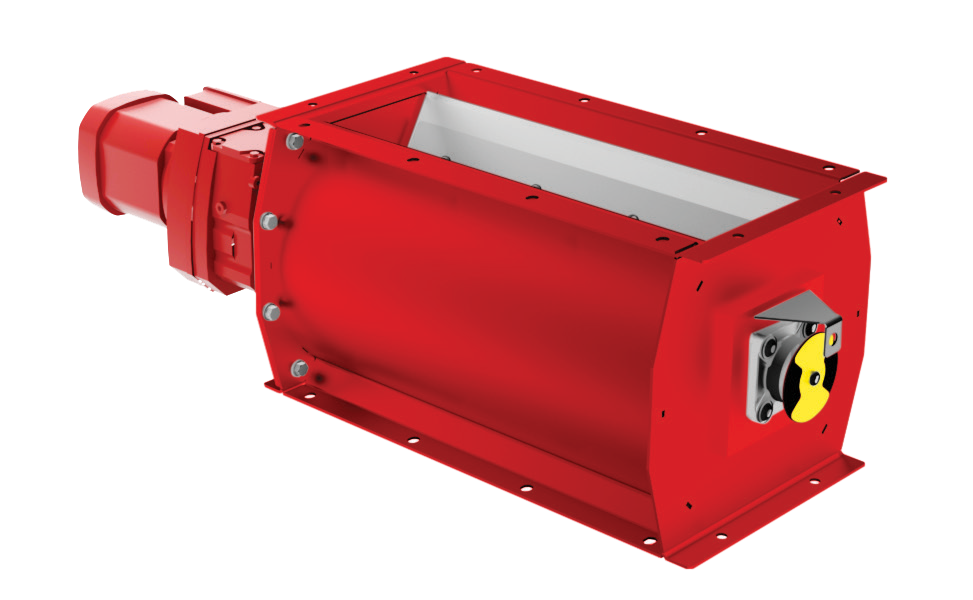

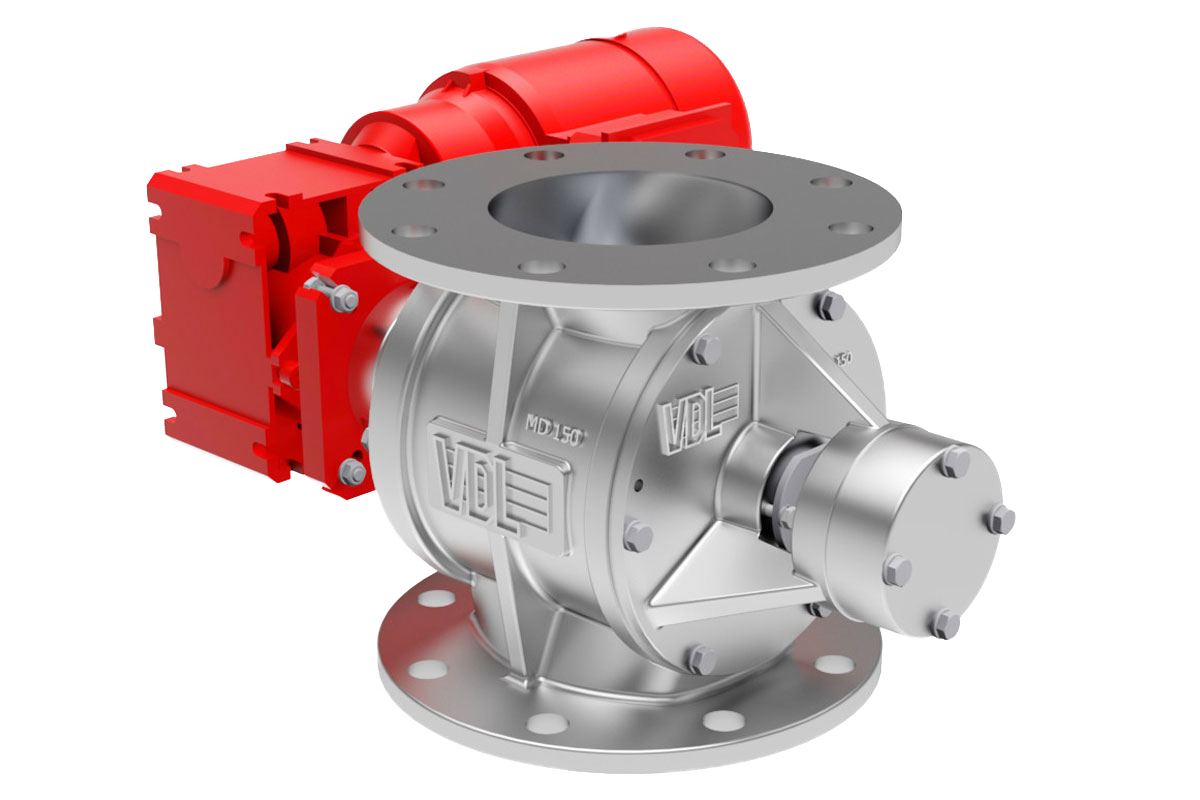

Rotary Valve MD Series

Applications

Ideal for feeding, metering and pneumatic conveying applications

Sizes: 6”, 8”, 10” & 12”

Order now!

Not sure which rotary valve to order?

Our engineering support team can help.

Simply tell us about your application using this short questionnaire. We’ll identify the right solution and provide a quote.

Specify this product

Get More Information on This Product

"*" indicates required fields