Fire & Explosion Mitigation

your single source supplier for fire and explosion isolation, suppression, and diversion needs.

Boss Products is committed to helping you meet and exceed today’s strict NFPA regulatory guidelines governing your industry. That is why we provide a full range of fire and explosion mitigation solutions - including prevention, isolation, diversion, and venting - which address potential hazards in the industrial filtration and process industries. Our staff bring decades of experience to the design, engineering, and installation of containment solutions for multi-application industrial dust collecting, bulk handling, and process systems. Based on this wealth of knowledge, Boss Products has developed and brought to market a family of SAFETY SMART solutions to work as individual components or as a seamless plantwide solution to meet most needs.

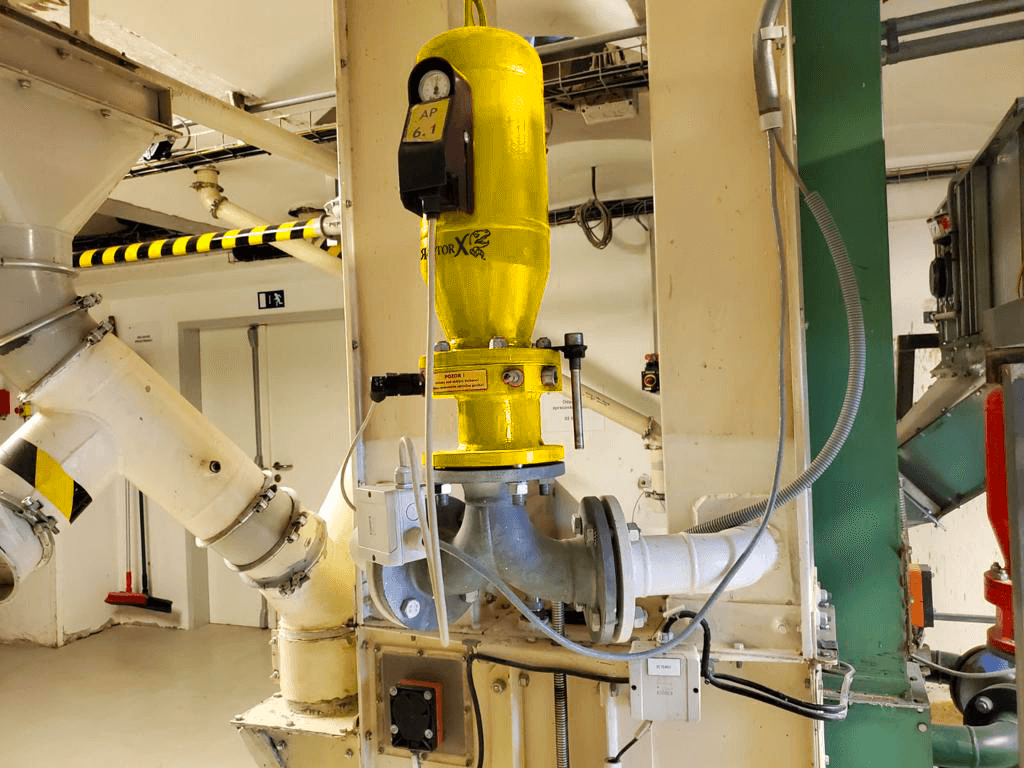

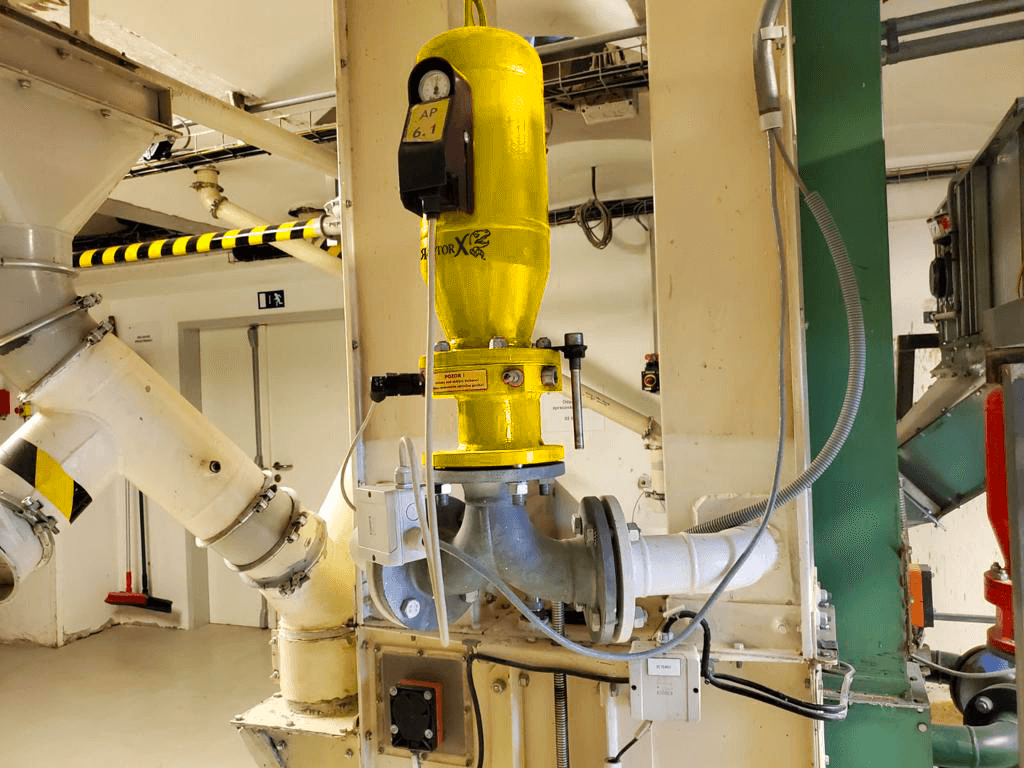

Explosion Isolation & Diversion

Explosion Venting

Fire & Explosion Prevention

Grain Elevator Hazard Monitoring