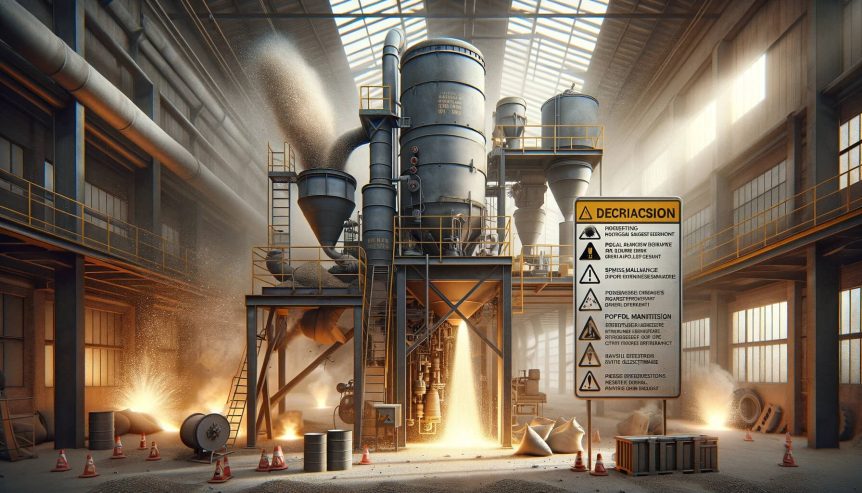

Dust collector explosions pose significant risks to industrial filtration and process industries, jeopardizing worker safety and causing substantial property damage. As a trusted provider of integrated Fire and Explosion Mitigation solutions, Boss Products is committed to helping industries address this critical issue effectively. In this article, we will delve into the causes of dust collector explosions, preventive measures, and how Boss Products’ solutions can safeguard your facility.

The Causes of Dust Collector Explosions

Dust collector explosions occur due to the presence of combustible dust particles in the air, mixing with oxygen and an ignition source. Several factors contribute to the risk of explosions, including the type of dust, particle size, and concentration. Common combustible dust materials include wood, metal, coal, and plastics. Understanding the properties of the dust in your facility is crucial for effective prevention.

Preventive Measures

Regular Inspection and Maintenance: Implementing a routine inspection and maintenance schedule for dust collectors is vital. Boss Products offers comprehensive maintenance plans to keep your systems in peak condition, reducing the risk of potential explosions.

Explosion Venting Systems: Boss Products provides advanced explosion venting systems that quickly redirect and mitigate the pressure and heat resulting from an explosion. These systems help minimize damage to equipment and protect workers.

Spark Detection and Extinguishing Systems: Employing spark detection and extinguishing systems can detect sparks and flames in the dust collection system, triggering an immediate response to prevent escalation into a full-scale explosion.

Grounding and Bonding: Boss Products emphasizes the importance of proper grounding and bonding to prevent static electricity buildup, reducing the likelihood of ignition.

Boss Products’ Solutions

Flameless Venting Technology: Boss Products’ flameless venting solutions offer a safer alternative to traditional venting methods. By suppressing flames before they exit the vent, these systems minimize the risk of secondary fires.

Explosion Isolation Systems: Our explosion isolation systems prevent explosions from spreading to other parts of the facility, limiting damage and maintaining worker safety.

Integrated Monitoring and Control: Boss Products provides state-of-the-art monitoring and control systems that offer real-time data on dust collector conditions, ensuring timely responses to potential hazards.

Dust collector explosions are preventable with the right measures in place. Boss Products’ comprehensive Fire and Explosion Mitigation solutions offer industrial filtration and process industries the peace of mind they need to operate safely and efficiently. By understanding the causes of dust collector explosions and implementing preventive measures, you can safeguard your facility and protect your workforce from potential hazards.