Protecting Milling & Grain Facilities from Fire & Explosion Hazards

Risks in Milling & Grain Operations

Grain dust is highly combustible — and the equipment that keeps your facility moving can also create the perfect conditions for an explosion.

According to NFPA and OSHA, equipment like hammer mills, bucket elevators, and dust collectors are among the most common sources of combustible dust explosions. Milling and grain handling facilities face vulnerable points where ignition can easily occur. With confined spaces and continuous dust generation, even a small spark can lead to a catastrophic event.

Together, these hazards put workers, equipment, and entire facilities at risk. That’s why compliance with the new NFPA 660 standard Chapter 21 is more critical than ever.

Applications

Complete Protection:

Passive + Active Safety Solutions

Passive Solutions

Active Solutions

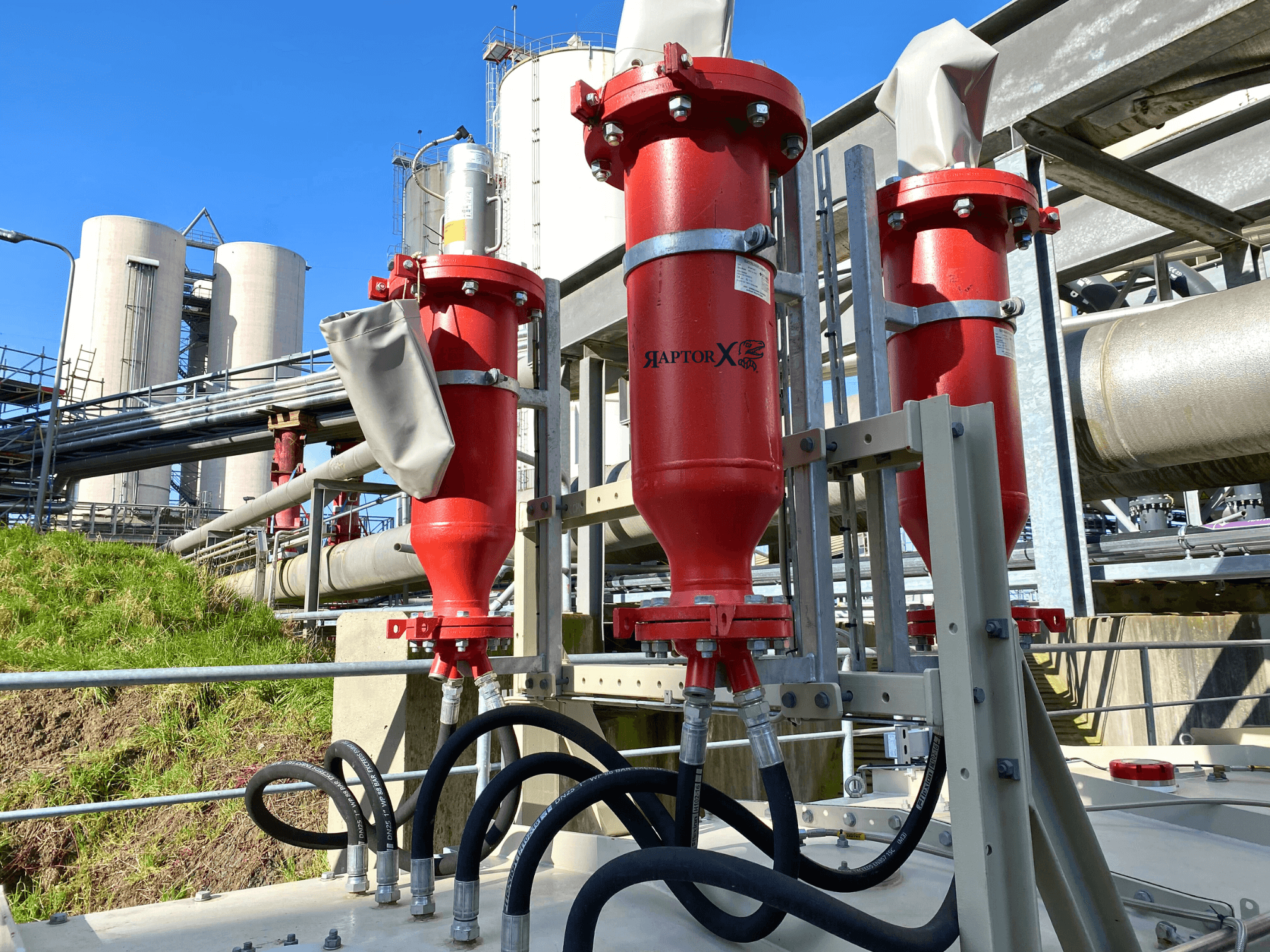

Explosion Suppression Made For Your Applications

Key benefits

- Quick installation with instant activation

- Low-maintenance design that maximizes uptime

- Peace of mind for your milling & grain operations

Reach Out To Our Team

Have a question? Interested in learning more about our fire & explosion mitigation solutions?

Provide us with a few details and one of our specialists will be in touch.

Alternatively, give us a call at 210.664.4200

"*" indicates required fields